Swamp Cooler Repair & Service

Evaporative Cooling: Perfect for Desert Climates

Parts of Los Angeles and the surrounding areas are ideal for evaporative or swamp coolers. Coastal regions can carry too much humidity, but most inland districts are dry enough for a swamp cooler’s simple, cost-effective technology.

Equipment and operating costs are a fraction of air conditioning, with its complex, energy-intensive systems reliant on the refrigeration cycle.

But the hard water of metro Los Angeles and Orange County can wreak havoc on a swamp cooler. So, like any other large cooling system in Southern California, a swamp cooler may need the TLC of a professional at times.

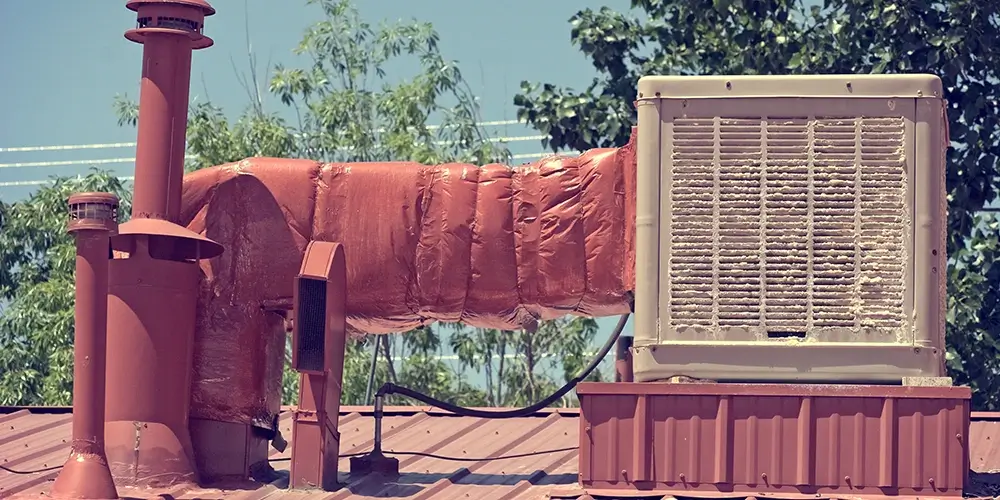

This is especially true of massive commercial evaporative coolers.

The basic principles of a swamp cooler are similar to an air conditioner, but the mechanics are very different. They must have dry air. They’re counterproductive in a moist climate, making clammy, humid air even clammier.

What Are Evaporative or Swamp Coolers?

Evaporation is the process of liquid turning to gas. It takes heat energy to produce evaporation, like the heat energy of a gas flame when you boil away the water in a saucepan. Don’t leave the house when you do!

If you force the evaporation by another method, the heat “debt” still has to be paid. It’s extracted from the surrounding area.

Methods of forcing evaporation than by direct heat include:

- Pressure reduction, used in the refrigeration cycle,

- Moving air over a liquid surface.

Evaporative coolers use the second principle, drawing air over damp pads to cool a building.

While air conditioners work in sealed indoor environments and repeatedly re-circulate the same air, evaporative coolers work in non-sealed environments. Instead of recirculating the same air, they continually pull in fresh outside air.

Parts of a Swamp Cooler

An evaporative cooler has four main components:

- A water tank

- A pump

- Cooling pads

- A ventilator motor attached to a fan

The pump saturates the cooling pads with water. The fan draws outdoor air over the saturated cooling pads, triggering evaporation and reducing temperatures in the building.

More sophisticated coolers come equipped with a filter to block dust and other particles.

Sometimes, evaporative coolers are attached to ductwork like a central air conditioner. But most coolers circulate air directly into a room.

How Much Water Does a Swamp Cooler Use?

The rate of water consumption by an evaporative cooler depends on several factors, including:

- Size of the unit

- Humidity in the air

- Dryness of the cooling pads

- Operating temperature

On average, a properly operating swamp cooler will use between three and 15 gallons (11-57 liters) of water per hour.

You can switch the cooler to fan mode at night, where it uses no water at all.

Swamp Cooler Maintenance

Folks handy with a wrench may be able to perform their own swamp cooler maintenance. Do NOT attempt to work on a commercial evaporative system unless you know what you’re doing or climb onto a roof if you’re unaccustomed to rooftops.

The first maintenance stage comes in the spring when we prep the cooler for use. Steps include:

- Replacing cooler panels.

- Tensioning the fan motor belt.

- Oiling the blower assembly and motor.

- Testing the float valve.

- Testing the motor and recirculating pump.

- Testing the thermostat.

- Inspecting for leaks.

- Tightening all electrical connections.

- Removing any remaining mineral residue.

- Checking the tank for signs of cracking.

- Cleaning the cabinet interior and clearing debris.

- Sanitizing the system with a bleach solution.

- And much more!

The next phase of maintenance takes place in mid-summer. Steps include:

- Checking water levels.

- Re-checking the float valve.

- Assessing the condition of the float pads; replacing them if necessary.

- Checking for mineral residue.

- Rechecking the condition of the pump, fan belt, and motor.

The final phase of routine evaporative cooler maintenance is winterization. Steps include:

- Draining the water tank.

- Removing any mineral residue.

- Checking the tank for signs of cracking.

- Clearing clogs in the water circulation system.

- Clearing remaining water from the cooler’s lines.

- Inspecting for leaks.

- Covering the cooler for winter.

At West Coast Chief Repair, we can help you set up a maintenance schedule designed for your cooler model and your use pattern.

We’ll make sure your evaporative cooling system operates at peak efficiency when you need it most.

When to Call a Professional

If you don’t feel comfortable performing any of the tasks in the maintenance checklist, or if something isn’t working correctly, call us. We’ll get your swamp cooler up and running again.

Evaporative Swamp Cooler Problems

Evaporative coolers are much simpler than conditioners. Despite this, they can develop a range of problems that decrease their operating efficiency or cause them to stop working altogether.

Mineral buildup is common in hard water areas like LA.

Evaporating water leaves minerals. The more minerals the water contains, the faster mineral buildup occurs.

Eventually, this buildup clogs the vents and pads and blocks airflow.

There are several ways to reduce mineral buildup prevention. Let us help you decide which is best for you:

- Zinc anode in the reservoir.

- A reservoir overflow.

- Water filter.

- Treatment tablets.

Mold is another common problem with swamp coolers.

Warmth and moisture create a breeding ground for mold and fungus. Portions of the cooler exposed to the heat and sun are significantly warmer; they may as well hang a shingle: “All mold welcome here!”

There are non-toxic ways to deal with mold and fungus growth. We’ll go over these with you during a service call.

Swamp Cooler Troubleshooting & Repair

Most of the problems affecting an evaporative cooler boil down to a combination of things and not a single part failure. For example, excessive water may indicate:

- An improperly set float valve inside the water tank.

- Leaking float valve seals.

- Improper storage of the cooler during periods of nonuse.

Potential causes of insufficient airflow include:

- A loose or damaged belt on the ventilator motor.

- The fan belt or pulleys.

- Installation of the unit in a location with inadequate clearance for ventilation.

An evaporative cooler that won’t start may have damaged components like:

- Wiring.

- Switch.

- Ventilator motor.

A unit that doesn’t produce enough cooling power may have operating issues, including:

- Lack of adequate water saturation in the cooling pads.

- A malfunctioning pump.

- Clogs in the water recirculation system.

Count on West Chief Repair for Help

Whether you need a repair, seasonal maintenance, or a bit of advice, the team at West Coast Chief Repair is here to help.

We understand evaporative coolers and how they work, so you can trust us to identify the problem and get it fixed quickly.

We also offer a wide range of other HVAC services for residential and commercial customers in Los Angeles and the surrounding areas.

Our services include:

- Air conditioning repair & service

- Heating repair & service

- HVAC maintenance plans

- Commercial HVAC service & repair

And much more!

If you’re having trouble with your swamp cooler or any other heating or cooling system, don’t hesitate to call us.